In the field of Bicycle Storage, a 1:1 ratio of upper-tier to lower-tier racks is the conventional installation method. As one of the professional two tier bike rack manufacturers in China, we offer a more flexible solution combining Vertical bike Rack and Horizontal Sliding Bike Rack to adapt to diverse space optimization needs.

This article examines the technical and economic advantages of our parking system’s dynamic ratios and demonstrates how they enhance space efficiency .

Most conventional double-decker bike racks employ :

✅ Upper Tier: Pull-out Classic Bike Rack / Direct Pressure Bike Rack

✅ Lower Tier: Fixed Bike rack,

Installed in a rigid 1:1 ratio, this mature design ensures reliable operation and accessibility.

Our double tier bike rack system features:

✅ Upper Tier: Vertical lifting structure (elevator-style operation) for effortless bike loading.

✅ Lower Tier: Horizontally sliding racks for space-efficient storage and easy retrieval.

A. Space Efficiency:

Spacing requirements vary by tier:

For a 10° installation angle (Other angles)

Upper tier: Requires 500–600mm spacing

Lower tier: Only 240mm spacing needed (excluding shared sliding space)

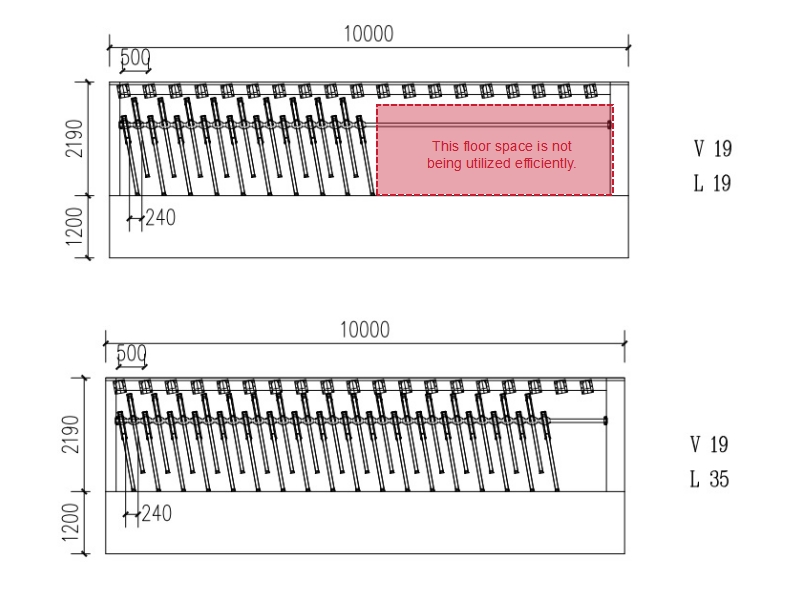

A 1:1 ratio wastes floor space, while dynamic ratios increase capacity by 42%.

(Refer to the table and images below.)

Space Comparison (10-meter length):

| Configuration | Parking Capacity | Component Breakdown |

| Traditional 1:1 | 38 spaces | 19 upper + 19 lower racks |

| Optimized Dynamic | 54 spaces | 19 upper + 35 lower racks |

B. Economic Advantages

Using a dynamic ratio to match upper and lower bike racks (instead of a fixed 1:1 ratio) significantly improves cost efficiency and space utilization within the same site area:

Lower Purchase Costs

The lower tier bike rack has a simpler mechanical structure than the upper tier bike rack, giving it a per-unit cost advantage. A rigid 1:1 pairing would unnecessarily increase procurement expenses.

Reduced Transportation Costs

Due to their simplified design, lower tier bike rack have a smaller packing volume. A 1:1 configuration increases total shipment volume, whereas a dynamic ratio optimizes loading space , thereby cutting logistics costs.

Conclusion: Dynamic ratio matching is the optimal solution for maximizing both space efficiency and cost-effectiveness.

We provide data-driven solutions tailored to your needs:

Samples/Wholesale: Recommended 1:2 ratio.

Projects: Site-specific optimization by using a dynamic ratio (provide dimensions for a customized plan)

Our technical team will calculate your ideal configuration – [submit your site details] for a free assessment.

Conclusion

Whether using traditional 1:1 racks or our dynamic-ratio system, the goal remains maximizing parking efficiency. Through innovative engineering, we deliver adaptable, cost-effective solutions.

Contact Us for a Space Optimization Proposal.